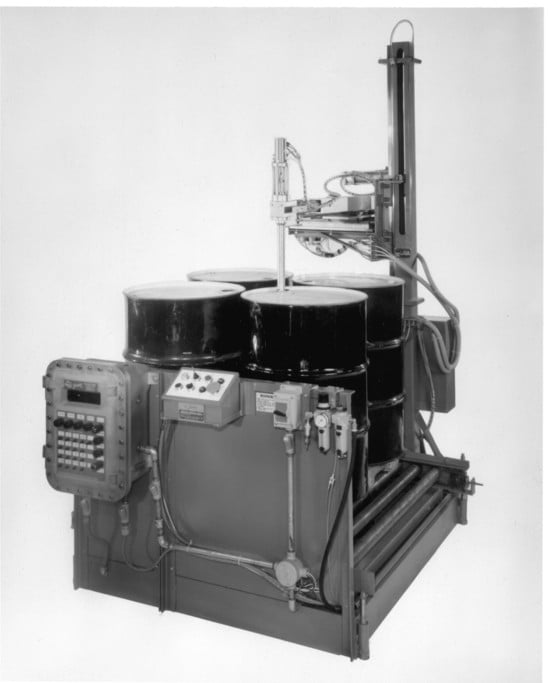

EF1/4X Sub Surface Drum/Tote Filler

Range of Products:

Any foaming or nonfoaming food, chemical, or petroleum product which will flow, settle out in the container, and does not contain hard solids, Machines are available in brass and steel (standard), 316 stainless steel, or sanitary stainless steel product contact parts. to suit a wide range of products.

Range of Containers:

Any free-standing metal, glass, or plastic container for 55-gallon drums. Filling lances are available for containers with openings as small as 35 mm (1-3/8").

Accuracy:

The 2.273 kgl or 5,000 lb. scale is a proven heavy-duty design specially adapted to the filling operation. Accuracy is within +-0.5% when the machine is properly installed and operated.

Installation:

The EF1/4X filler may be quickly installed by your plant personnel. The scale controller gets plugged into an electrical outlet. A 3/8" airline from plant air is to be connected in a filter.

Maintenance:

Sturdy design and construction guarantee many years of service. No special tools are needed for adjustment.

Operation:

The operator places all bung openings toward the center of the pallet with the caps out. Roll pallet on the filling platform. The operator aligns the filling lance to the drum opening. They then press the start button. The electronic scale auto tares and the filling lance will descend to the bottom of the drum and start the filling cycle. After a time period, the lance will start to rise and will stop before it comes out of the drum. When all four drums are filled, the operator exits the pallet and starts operation on another set.

Supply of Product:

The EF1/4X filler may be supplied from any non-surging source with a constant supply pressure in the range from gravity to 40 p.s.i.g.

Change of Product:

To change the product, the filling system may be drained and flushed down with solvent. For a complete cleaning, the filling head may be disassembled by the operator.

Noise Control:

Cylinders exhaust through ports with mufflers.

A level 20 db at 1M.

Safety:

The machine is equipped with a quick shut-off button for the operator to interrupt the fill. The system is equipped with a pneumatic fail-safe to shut off flow product if air pressure is lost.

Requirements

Personnel

One operator, unskilled. The operator has time to close and seal the bungs while the next set of containers fill.

Air

80 1/min. a15.6 kg/sq. em. {3cu. ft./min. at 80 p.s.i.) or 22 s.c.f.m. at 80 p.s.i.

Electric

110/120 volts, 50 or 60hz (cycles), 1 phase, grounded, clean. The scale controller classification is NEMA 4X, liquid tight.

Standard Features:

- Load cell base 48" x 48".

- Load cell capacity 5000 lbs.

- Electrics in 110 vac 50/60 cycle 1 phase.

- Two-stage fill-dribble flow.

- Safety shut off.

- Brass and steel wetted contact parts.

- Welded steel frame, enamel painted surface.

- Rollers on the filling platform.

- Electronic scale indicator in NEMA4X stainless enclosure.

- Programmed pneumatic sequential controls mounted in NEMA 1 enclosure complete with manual overrides, visual indicators, filter regulator, and lubricator.

Optional Features:

- Explosion-proof electrics.

- Epoxy-painted frame.

- Operation indicator package.

- Motorized platform rollers.

- Hazard environmental load cell/base.

- 316 Stainless steel wetted contact parts.

- Gravity infeed discharge conveyors 10ft. sections.

Shipping:

Shipped in two crates. Some assembly is required.

Approximate shipping weight:

- Crate 1: 2,300 lbs. (scale)

- Crate 2: 1,300 lbs. (upright)

Approximate shipping measurements:

- Crate 1: 97" length. 70" width, 49" height

- Crate 2: 105" length, 72" width, 42" height